Winding through Hungary

Trenchless International April 7, 2015

Budapest has become a model city for spiral-wound pipe rehabilitation from years of consistent application of the technology over several kilometres since 2010. Here, we look at the technology’s latest large profile rehabilitation project in the north-east of Budapest.

Budapest Sewage Works operates 5,400 km of sewer system under the city.

Underneath the city also runs a 730 m long cement pipe with a diameter of 1,400 x 2,100 mm that drains collected rain and wastewater from district 13, in the north-east of Budapest into the wastewater treatment plant.

The cement pipe was in a badly corroded state. The combined wastewater sewer, which has been in operation since 1907, exhibited material fatigue due to non-stop operation over the years, as well as cracks and damage due to corrosion.

Bacteria and caustic sulphuric acid inside the pipes had attacked the cement even though the concentration is low due to the common draining of wastewater and rainwater. The damage also decreased the structural stability of the concrete sewer.

SEKISUI SPR with construction partner Agriapipe were selected to rehabilitate 565 m of the cement pipe in areas where it was badly corroded.

The spiral-wound technology from SEKISUI SPR has been a familiar rehabilitation solution for the city of Budapest since 2010.

Agriapipe Managing Director Zoltán Varga said “Since the sewer network of Budapest features varying diameters and shapes, the spiral-wound technology is an ideal solution for operators.

It provides a rehabilitation process for all standard diameters in circular form, but also for the most diverse custom shapes, such as box- or mouth-shaped, or even egg-shaped profiles up to 5,500 mm.”

A central aspect in the selection of the spiral-wound method when it was initially selected was its ability to meet the requirement that the structural integrity of the old structures being rehabilitated must be re-established.

It was an additional advantage that work can be carried out exclusively through existing manholes so that there are hardly any hindrances for the local residents as well as the street traffic of this megacity during the rehabilitation.

The egg-shaped sewer in need of rehabilitation was located under a very busy main road, Pozsonyi Street, in the 13th district of downtown Budapest.

Buses travel through the street every 5 minutes in two lanes running in each direction. For rehabilitation through standard manholes, only a few metres around the access needed to be blocked off for the equipment and the rehabilitation vehicle.

There was hardly any hindrance for traffic above ground even though the rehabilitation project underground was many metres in length.

Winding during controlled live flow

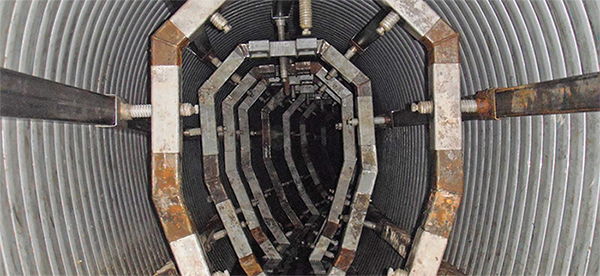

The 565 m long ailing sewer section was rehabilitated with the SPR Spiral-Wound method, by winding a steel-reinforced profile strip of PVC-U into a new highly resistant plastics inner layer directly within the host pipe.

To achieve this, the guide frame of the Spiral-Wound machine was lowered through a standard manhole into the rehabilitation section, installed into the host pipe directly and adjusted to the egg-shaped profile of the sewer while taking the statically required annular space

into account.

The 52 spiral-wound pipe spools stationed one after another above ground supplied the winding machine continuously with profile strips via the standard manhole.

The winding machine moved forward with every rotation by one profile width and locked the profile with a tongue-and-groove mechanism to create a watertight liner.

Once one of the 52 spiral-wound pipe spools was used up, the new profile strip was joined in a portable butt welding unit.

The winding process was carried out during controlled live flow in the old sewer.

A masonry wall was built at the upstream point so that the pump could transfer the combined wastewater into the following sewer section.

After about 250 m of rehabilitated sewer section, the stone wall was moved from the upstream point into the middle of the rehabilitation section to control the live flow for the remaining metres to be rehabilitated.

The goal was to maintain a water level of a maximum of 15 cm. Heavy rainfall posed a challenge occasionally as the water level rose to 1 m and the winding process had to be interrupted briefly.

Since the winding machine always remained stationed in the old sewer, winding could resume promptly after the water level had dropped and the pipe was cleaned.

Grouting

The winding process aimed to generate a defined annular space between the spiral-wound liner and the host pipe, which was filled with a high-strength grout in a subsequent work step.

The thickness of the annular space is determined according to the following principle: As little annular space as possible, but as much annular space as necessary for the required static properties.

In this case, the thickness was between 50 mm and 80 mm.

After the spiral-wound liner was completed, a bracing system was installed so that the annular space could be filled.

The bracing frames positioned the Spiral-Wound pipe liner according to the static requirements and thus prevented buoyancy, a positional deviation and deformation during the subsequent grouting.

The annular space was sealed after each 80 m section of installation length and filled up in layers with special grout to re-establish the static features of each section.

Durable corrosion protection of the concrete structure

In the long term, the new rehabilitated pipe offers an important operational advantage.

Since the steel-reinforced plastic spiral-wound pipe liner is not a temporary aid for installation, but rather remains a fixed design component of the rehabilitation solution, it permanently protects the

host pipe and the filled-in annular space grout against mechanical abrasion and attack by the combined wastewater.

In the end, the SPR spiral-wound pipe liner therefore serves as formwork for a new mineral grouting of the old sewer and as a reliable protective coating over many years that separates the concrete structure from the combined wastewater.

The smooth and abrasion-resistant surface of the SPR liner will improve the hydraulic capacity minimum for the next 50 years of continuous operation, and compensates for the minimal cross-section reduction of the host pipe.

A fine conclusion

As the final step, the reconnection of the grouting sections and laterals were done as usual.

During this year’s rehabilitation project, the SPR technology not only proved to be durable and economic, but also a rehabilitation method that can be accomplished comparatively quickly.

After the city ordered the works, successful completion of the rehabilitation of the sewer section was planned for just 15 weeks later on the construction schedule.

Variations of spiral-wound technology

The spiral-wound pipe method is based on the principle of the mechanical in-situ production of a liner made of extruded plastic profile strips.

The process produces liners for nominal widths of 200-5,500 mm by a winding machine that pushes the spiral-wound profile in the host pipe or – depending on the process version – leads the spiral-wound liner through the structure.