Pipe Rehabilitation with Spirally Wound Technologies

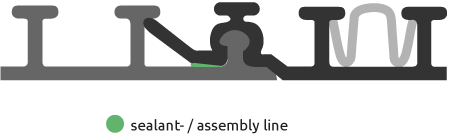

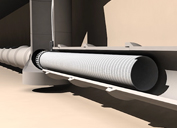

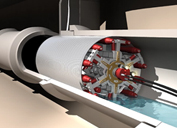

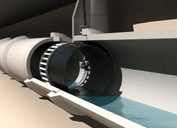

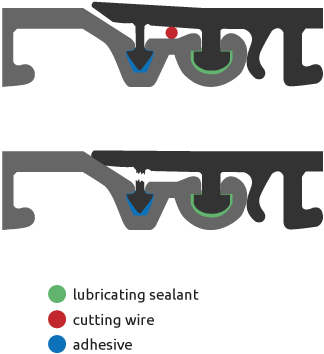

Spirally wound technologies manufacture the liner at the job site by spirally winding a PVC or polyethylene (HDPE) continuous plastic strip of various profiles directly into the deteriorated pipe forming a continuous watertight liner by a special winding machine. The plastic profile that forms the liner is provided in various sizes and thicknesses and some even have steel reinforcement. The edges of the profiles are interlocked by the machine as it is producing the liner inside the deteriorated pipe or welded together depending on the material of the profile. Some of the technologies are close-fit and some require grouting. As a result we get a fully structural, strong and lightweight liner with the least possible excavation or no excavation work at all. These technologies are recommended to rehabilitate gravity pipe lines with circular, egg or custom shapes from 150mm to 5500mm diameter sizes.

The processes developed by Ribloc of Australia and Sekisui of Japan are carried out in collaboration with SEKISUI CHEMICAL GMBH.

SPR EX (Expanda)

| System | gravity |

| Transported Medium | sewage, industrial waste water, rainwater |

| Host Pipe material | concrete, clay, brick, azbestos cement, KG PVC, cast iron |

| Diameter | 150-1050 |

| Shape | circular |

| Fabrication | liner is produced in the host pipe by winding the plastic profile manufactured from pipe grade PVC |

| Comment | strong and lightwieght structural liner, close-fit with host pipe |

SPR RO (Rotaloc)

| System | gravity |

| Transported Medium | sewage, industrial waste water, rainwater |

| Host Pipe material | concrete, clay, brick, azbestos cement, KG PVC, cast iron |

| Diameter | 800-1800 |

| Shape | circular |

| Fabrication | liner is produced in the host pipe by winding the plastic profile manufactured from pipe grade PVC with a machine that interlocks the edges of the profile |

| Comment | strong and lightwieght structural liner, close-fit with host pipe |

SPR PE (Ribline)

| System | gravity |

| Transported Medium | sewage, industrial waste water, rainwater |

| Host Pipe material | concrete, clay, brick, azbestos cement, KG PVC, cast iron |

| Diameter | 900-3000 |

| Shape | circular |

| Fabrication | liner is produced in the host pipe by winding the profile manufactured from pipe grade high density polyethylene (HDPE) with embedded steel reinforcement with a machine that welds together the edges of the profile |

| Comment | strong and lightwieght structural liner, close-fit with host pipe |

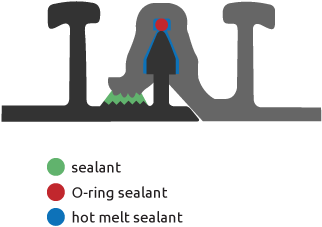

SPR

| System | gravity |

| Transported Medium | sewage, industrial waste water, rainwater |

| Host Pipe material | concrete, clay, brick, azbestos cement, KG PVC, cast iron |

| Diameter (mm, circular) | 800-5500* |

| Dimensions (mm, egg) | from 1000/1500 |

| Shape | circular, egg, rectangular, custom** |

| Fabrication | liner is produced in the host pipe by interlocking the PVC profile strips that have steel reinforcement |

| Comment | the technology requires grouting |

*for larger pipe diameter, please contact us

**for custom pipe shapes, please contact us