Partial Repairs

Partial Repair with glued hose

The repair involves gluing a short hose made of resin-soaked felt or glass cloth, or a combination of both, to the defective areas. The impregnated hose is placed in the desired location using an inflatable rubber packer. The procedure can also be used successfully to repair local defects in newly constructed pipelines.

Partial Repair with Weco Rings

To repair a damaged, leaking socket of a pipe network we place internal WECO rings in the pipes. The WECO system means a special internal rubber cuff that is pressed against the inner wall of the host pipe by stainless steel rings. This technology provides a repair solution for large diameter gas, water, sewage and industrial pipe sockets up to a maximum diameter of 3m.

Partial Repair with Quick-Lock

For the repair of the sockets of smaller diameter pipes we offer the technology called QUICK-LOCK. The QUICK-LOCK profiles can be applied from 150 mm diameter to both pressure and gravity pipes.

Sewer robot

The self-operated sewer robots are used for solving operational problems in networks, e.g.: removal of stuck roots, as well as for preparatory and finishing works of lining renovations. They are used for the removal of obstructions to the installation of lining pipes, e.g. inlets, concrete spills, etc., and for the professional opening of connections to the ridge of lined pipes.

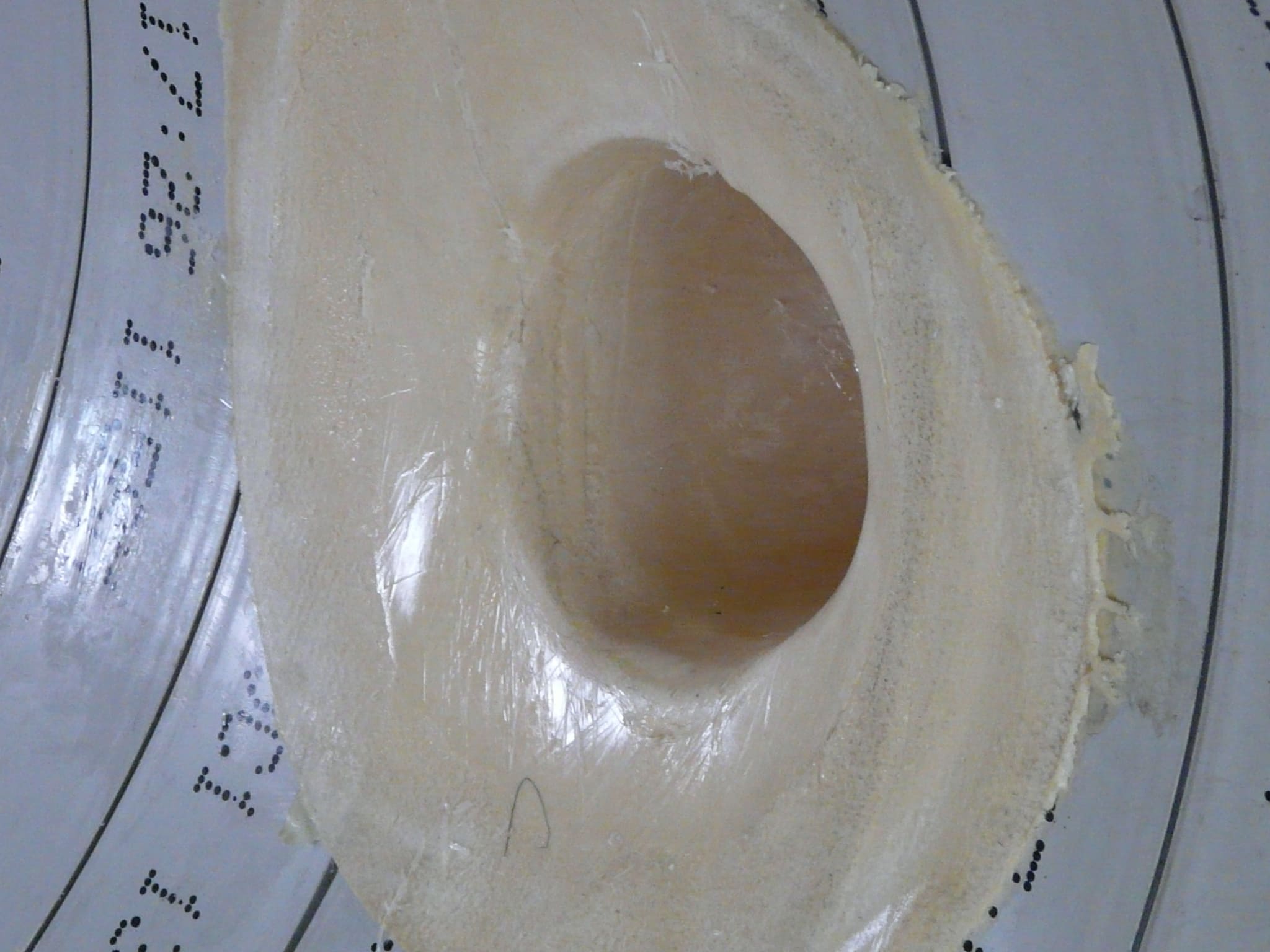

Repairing domestic connections with a so called "hat"

The repair of connections directly to the sewer is carried out by gluing a special resin-impregnated bonding agent consisting of felt, glass fibre or a combination of these. The so-called hat-joint is placed at the connection point using inflatable rubber packing wheels. This solution is used to seal the pipe end at the connection point during the lining renewal of the connection pipes.

Shaft Renovation

Shafts installed with different purposes are important elements of gravity sewers. The tightness of these elements are of high importance. During the course of our renovation process we install a lining profile in the structure. These liners are either made of standard KGP PVC elements or custom made PE or GRP bases depending on the unique requirements.

The connection of the pipes entering and leaving these shafts is completely watertight. Connections are inside the pipes. This procedure is our own development and it is currently under patent procedure. The gap between the liner and the old pipe wall is either grouted or filled up.