Pipe Rehabilitation with CIPP Technologies

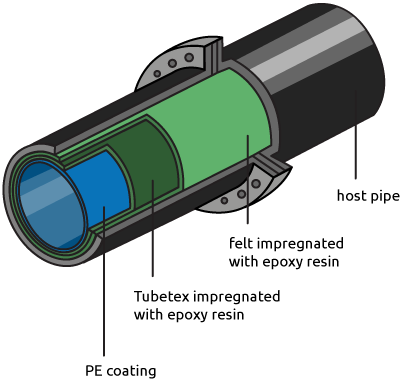

CIPP technologies are the group of procedures that use cured in place pipes to rehabilitate deteriorated pipes. We install a liner inside the cleaned pipe section. The liner consists of a textile that is able to carry the resin, resin and a coating. The textile material is installed in the pipe after impregnation with epoxy resin. We keep the liner under pressure until the resin cures. Curing can be achieved by higher temperature or UV light.

The procedure is also suitable for the lining renovation of domestic connection lines. The Brawoliner hose also bridges directional breaks and size variations in the inlet duct.

We use the Process Phoenix technology. Due to the different hose types this No-Dig technology can be applied to water, gas, industrial waste water and rainwater pipes too.

The "two-in-one" system with the so-called SOLTA®LINER XTRA process allows the installation of a special hose during the renovation. The finished tube liner provides space for the signal transmission cables.

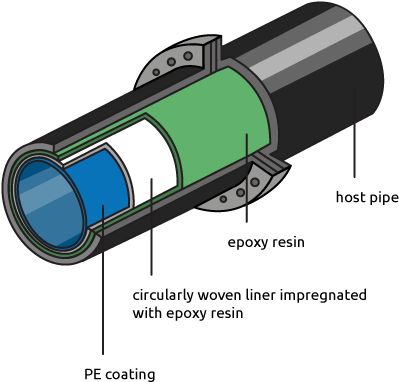

Tubetex Water

| System | pressure |

| Transported Medium | potable water, industrial waste water, sewage, fire water, oil* |

| Host Pipe material | steel, cast iron, reinforced concrete |

| Diameter | 80-1200 mm |

| Shape | circular |

| Working Pressure | 1-32 bar |

| Fabrication | circular woven hose PE or TPU coating |

| Comment | internal lining with adhesion |

*applicable with special considerations

Tubetex Gas

| System | pressure |

| Transported Medium | gas |

| Host Pipe material | steel, cast iron |

| Diameter | 80-1200 mm |

| Shape | circular |

| Working Pressure | 1-32 bar |

| Fabrication | circularly woven liner with hyrtel coating |

| Comment | internal lining with adhesion |

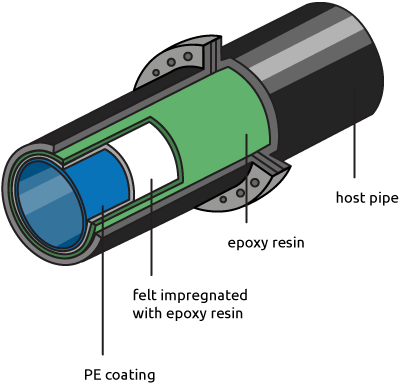

Nordiwall

| System | gravity |

| Transported Medium | sewage, rain water, industrial waste water |

| Host Pipe material | concrete, clay, azbestos cement, KG PVC, cast iron |

| Diameter (mm, for circular profile) | 200-1050 mm |

| Dimensions (mm, for egg profile) | 200/300-900/1350 mm |

| Shape | circular, egg |

| Fabrication | polyester needle felt with PE coating |

| Comment | internal lining with adhesion |

Nordiwall Flex

| System | gravity |

| Transported Medium | sewage, rain water, industrial waste water |

| Host Pipe material | concrete, clay, azbestos cement, KG PVC, cast iron |

| Diameter (mm, for circular profile) | 150-1050 mm |

| Dimensions (mm, for egg profile) | 200/300-900/1350 mm |

| Shape | circular, egg |

| Fabrication | single or double layer polyester needle felt structure with polypropylene coating, wallthickness from 2.5 to 8.5mm. |

| Comment | internal lining with adhesion |

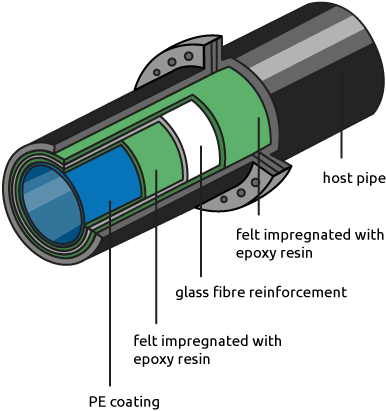

Nordiflow

| System | pressure/gravity |

| Transported Medium | potable water, industrial waste water, sewage, rainwater, industrial water* |

| Host Pipe material | concrete, clay, asbestos cement, PVC, cast iron, steel |

| Diameter (mm, for circular profile) | 150-1400 mm |

| Dimensions (mm, for egg profile) | 200/300-900/1350 mm |

| Shape | circular, egg (gravity) |

| Fabrication | polyester needle felt hose with PE or PP coating and glass fibre or glass fabric reinforcement |

| Comment | internal lining with adhesion |

*applicable with special considerations

Combiliner

| System | pressure |

| Transported Medium | potable water, industrial waste water, sewage, fire water, oil* |

| Host Pipe material | steel, cast iron, reinforced concrete |

| Diameter | 80-1200 mm |

| Shape | circular |

| Working Pressure | 1-32 bar |

| Fabrication | circular woven hose with needle felt and PE or TPU coating |

| Comment | internal lining with adhesion |

*applicable with special considerations

Uniliner

| System | gravity |

| Transported Medium | sewage |

| Diameter | 100-1280 mm |

| Shape | circular, egg |

| Fabrication | needle felted felt hose with PE or PP coating |

| Comment | no glued connection between the old and the new pipe |

Brawoliner

| System | gravity |

| Transported Medium | sewage, industrial waste water, rainwater |

| Host Pipe material | concrete, PE, KG PVC, clay |

| Diameter | 70-250 mm |

| Shape | circular |

| Fabrication | circularly woven liner with polyurethane coating |

| Comment | internal lining with adhesion |